Hey there gurus.

I’m hoping for some advice on a little project I’m embarking on. My 6 year old son has recently become fascinated with the Rainbow Lorikeets that regularly visit our back verandah, and subsequently commissioned his pop (who’s a little more handy than his dad) to build him a nice Lorikeet bird box.

To make it a bit more fun, I was hoping to install a camera and stream live video, so we can keep an eye on who’s moved in and what they might be getting up to.

I’m pretty familiar with developing solutions with Raspberry Pi’s so I figured I’d go with a Raspi Zero 2 W, NoIR Camera and the official case which can house the Pi and the camera.

What I’m a bit unsure of is:

-

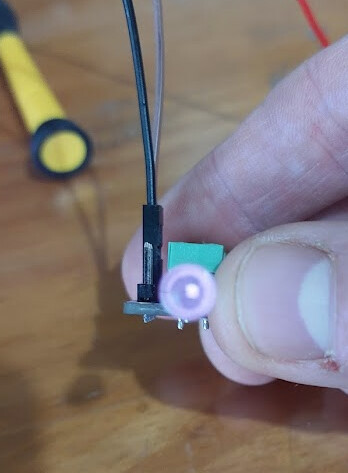

Do I need some additional light source for the camera? - something like this perhaps Super-bright 5mm IR LED - 940nm | Buy in Australia | ADA387 | Adafruit | Core Electronics which could be triggered by the GPIO pins

-

What is my best option to power something like this? Ideally I’d like to run this constantly off solar power, so I don’t need to run power to it (as it will be installed outdoors, up a tree). I assume I’ll need a small solar panel, battery and a controller of some sort to make this work, but any help with exactly what those parts would be (based on power requirements etc), would be greatly appreciated.

-

What’s the best software / script / library out there to stream the live video to our local network. I (preferably) just want to be able to view the activity from a web browser on a phone, tablet or PC. If the camera setup could be triggered by someone accessing the live feed, that would be ideal, especially from a power saving perspective.

Thanks in advance.