I have a machine that produces anywhere from 2000 to 5000 products per hour.

Depending on settings, adjustments and stops the actual hourly rate can vary.

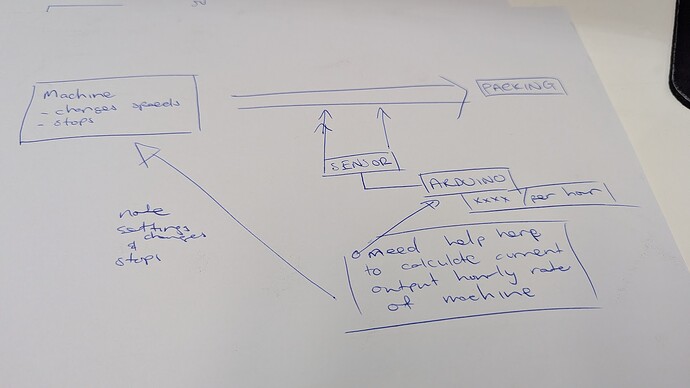

I want to place a sensor on the out feed of this machine that will count each product as it exits the machine.

I then want to use that count and some very [clever maths and code] to continuously recalculate the new speed as quickly as possible after stops and settings changes.

Can anyone help me with the [clever maths and code] part?

If you want someone to write the code for you, you are going to need to provide the details of exactly what controller you plan to use, the development environment used to develop and a clear list of the inputs and outputs.

I have already provide the math and how to at a high level and anything lower needs working to the chips in use.

e.g. will the controller have the ability to have an accurate time of day clock ?

What language will it be coded in?

How fast will the sensor get triggered (if the controller is too slow of busy it could miss the triggers, in which chase more advanced code is needed to deal with that and/or a different chip.

Hi Larry

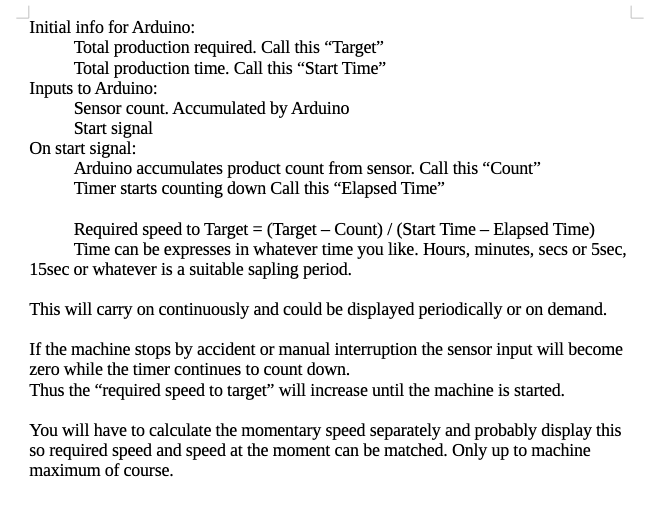

An idea for you. This could work and would not be as coding heavy as trying to count in 5 second or whatever blocks.Would probably require a bit of enterprising coding ut I will ave to leave that to the experts.

Would be interesting to see the results.

Cheers Bob