Lets do some rough math (I may have missed the number of LEDs somewhere, so that’s on me if I have)

Number of LEDs : 300

Assuming a max current of 60mA per led (may be 40 or 50 as actual exact numbers seems hard to come from, but for safety we go over not under).

300 * 0.06A = 18 Amps

Lets assume all the power is running from the power supply to the first LED (and some other assumptions about the copper used in the wire etc)

Then to push 18A over 1 wire over 1 Meter in distance, then the wire size should be a minimum of 4.928 mm2 (which will be about 2.5mm wire diameter (i.e. just the wire) so the insulation would be added to that. Lets go with about 1mm insulation thickness and we now have a physical thickness total of 5.5mm diameter.

Now when we see that, it MAY be ok for the application, by may be too thick to be practical. e.g. to connect to JST connectors or solder etc.

So what we can then do, is say have two runs (lets assume left and right hand side of the suit). I am assuming that both are a mirror of each other.

So now we only need to support 1/2 the current on each wire (going to each side); but that still needs 2.46mm2 (1.77 mm dia) so adding 1mm insulation, we have a wire now of 3.77mm and not 5.5mm

Now if we split into 4 sections (of equal or about the same number of leds) then (without doing the each one by one, assuming the current is 1/4 of the original)

We now only need 4 runs of 1.232 mm2 (1.25mm Dia)

so with insulation of 1mm about 3.25mm.

Assuming the power supply can deliver the full 18 Amps (for this example), then you would run all 4 power (Pos and ground) back to the one power supply. But this will depend on the power supply. e.g. One of my 20Amp/hr power supplies will only deliver a peek current of 3 Amps out the 5V usb port, so that power brick wont work.

BUT to get the current down to < 3Amps, a target would be abut 2Amps if max is 3 (some buffer room and losses). then you would need 9 Of them, so that’s way too many for this project.

So assuming we need the 18Amps @5 V (for 300 LEDs) then now we need to find suitable power supplies that can deliver 18Amps at 5V, or 2 * 9 Amps (assume you can split the power needs at 50%).

So… a bit of home work to see what power supplies you can find that are portable, and can output the needed power.

So if you can find 1 big power supply and use that as 5V via a power regulator to 3.3V (most uC have on onboard 3.3v regulator) then all the grounds are at the same reference, and things look simpler.

So we are looking at design considerations. Some of these will be dictated by the devices/firmware etc that is used. you can run over 1000 LEDs off the one controller pin (assuming you can clock out fast enough; which an ESP32 can)

So with a single power supply (if it can be found), you can have one big string with one uC so no sync needed.

Pro: Simpler design

Con: Bigger single power needs

A single LED failure will stop ever led after it.

May be harder to code to get the effects you want with chosen software/firmware.

(Like I said, I would just write the code from scratch, then I dont have any limits from ready made devices); But since I dont tend to use ready made, I cant comment on what may or may not work.

Now: If we need 2 power supplies, then we need to have the V go to two separate strings. But that is just the Power +V. we can still connect the gounds for a common ground, then have one big string, just first 1/2 from power supply 1, second 1/2 from power supply 2.

Same as above with controller/software.

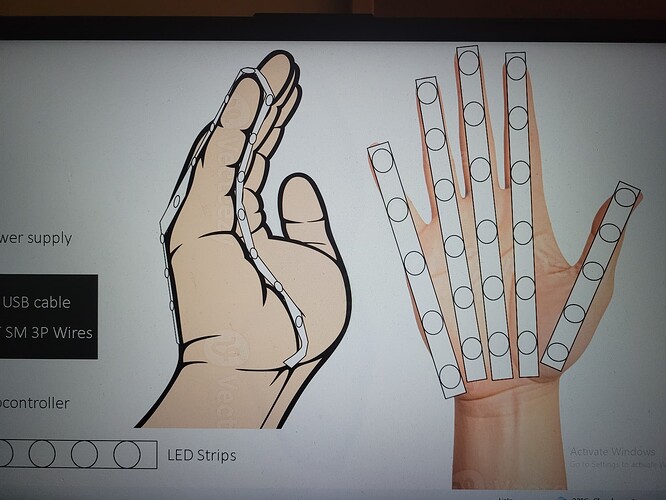

So, the key take away here is you start with knowing 100% you many leds and how they are broken up. I did see your image, but was not sure on the actual number of LEDs.

You then work out the power needs (worst case) add a buffer to that, then find what power supply options you have.

Once you know the how many supplies you need (1,2 3 …)

then you can work out the best way to wire those into the LED strips. As per my example above you need to define the max wire + insulation thickness that you can work with (i.e. the connectors/solder pad size etc.) This will dictate how many power injection points. But with 300 LEDs, I would have a min. of 2, but considering every point at which the LED strip is cut can be a power injection point, that will make it easy to work out. e.g. If you had 3 Segments per side Top (Solder/Arm), Upper Leg and Lower Leg, then you have got 3 easy power injection points per side… so a total of 6 back to the power supply.

Does that make sense ?

Firm up the exact number of LEDs, where the are and where the break points are.