I have been playing with the PiicoDev RFID module which is based on the MFRC522 chip.

ie: PiicoDev RFID Module (NFC 13.56MHz) | Buy in Australia | CE08086 | Core Electronics

Im just looking for some feedback from experience and/or some ideas.

I have the device up and working and can use more then one… and I understand RFID fairly well.

With the 14a RFID ideally we only want one card in range of the reader at the same time, this allows the identification and card selection based on the tags UID to be simple and works. But the 14a standards do allow more then one card to be on the reader at the same time and with the use of the anti-collision and tag select commands we can isolate and tags UID then select it, while all other cards stay quite.

My anti-collision code seems to be working with 2 cards.

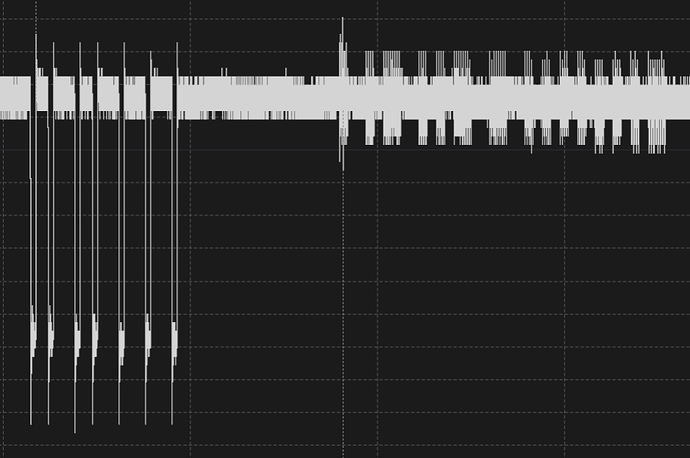

i.e. We send the REQA/WUPA then anti-collision/select level 1 (0x93 0x20) and we get the detected location of the first bit collision. I can then use that to select a part UID and get the remainder of the UID for 1 of the two cards.

i.e. the reader does detect the correct collision bit location and I can select one tag, then the other as needed.

But when I put 3 or more tags on the reader, i get nothing, just a time out. i.e. no data, no bit collision location, nothing.

Do we know if there is a limit on this chip to only work with 2 tags.

I have played with the field power levels and data bit and collision bit thresholds via the registers but still nothing.

So to be clear.

- Selecting reading/writing to a single tag - no problem

- Selecting one card from 2 cards on the reader (either one) - no problem.

- When 3 or more tags are on the reader, I get nothing.