Just a cool thing I stumbled on.

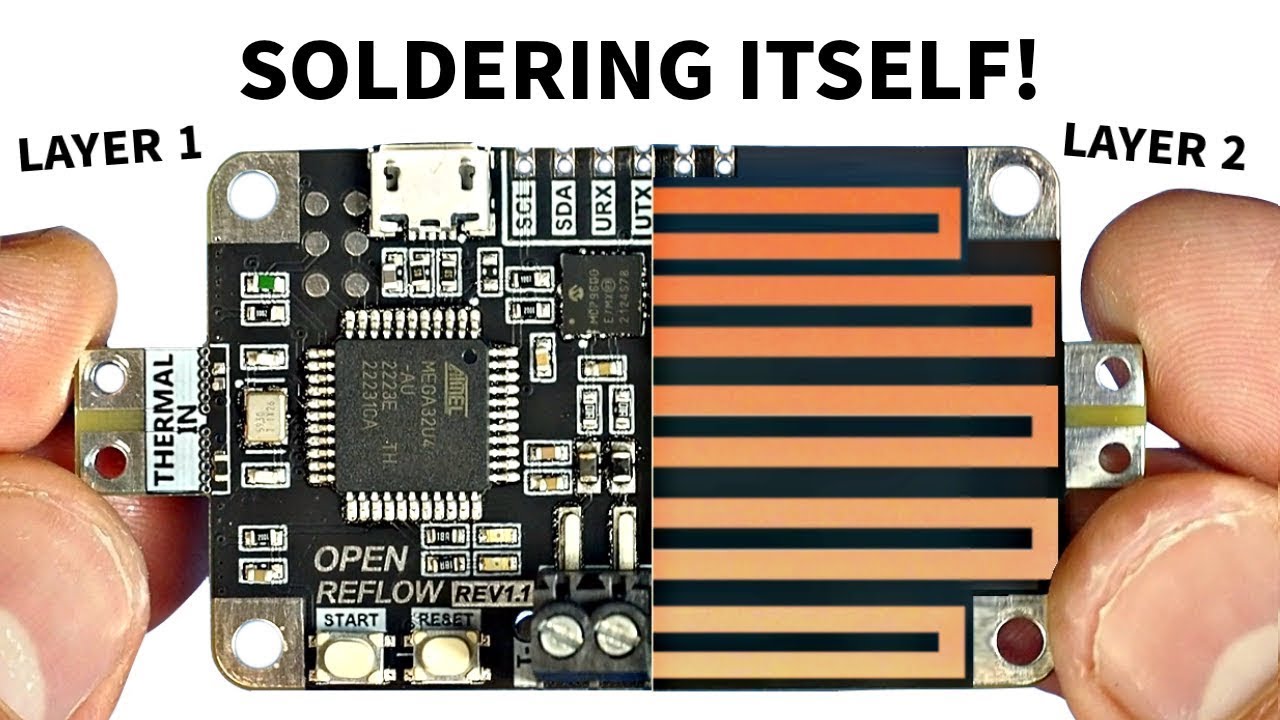

What he does is runs a trace through an inner layer of the PCB, instead of a ground plane. That acts as a resistor, putting a current through that creates heat. By applying the solder paste and surface mount components he can then get the board to construct itself. The first board he made with this was a controller board for the self soldering process. That meant after doing 1 manually he could then scale exponentially after that, well, theoretically.

Obviously, he only needs the self soldering capability once per board, so he shorts the trace to ground.

4 Likes

Hi Doug,

Thanks for sharing this. This is some serious mad scientist stuff!

What kind of mind thinks of something like RepRap soldering using your “ground plane”?

I suspect I will be pondering this all weekend wondering how viable it could be in practice. Either way it’s a super impressive demo.

1 Like

Hi All

Very interesting. Where did you find that?

Would not be much of a ground plane. All that stray inductance. OK maybe for low frequency work but believe me stray inductance can be just as problematic in the ground circuits as that in high side circuits. Possibly more so as quite often ground side stray inductance can me insidious as it is sometimes hard to track down. Could be hidden in the thickness (or lack of thickness) of a wire or similar. Even in a thin section of track.

In my humble opinion this heating element would be best left connected to nothing. Just let it sit there.

Cheers Bob

1 Like

It was from hackaday.com The google news feed on my phone pulls in articles from there, from time to time. The same maker has some PCB based actuators over at https://flexar.io/ that are interesting too.

1 Like

what are the applications of these PCBs?

It’s probably a “Why? Because I can” kind of thing, or just for the hobbyist.

It’s very nifty, but you’d probably be better off making a home reflow hotplate, it’d be much more useful…

Though, I wonder if this approach could be used to make a reflow hotplate? You’d have good control on the heating area, as it’d be just a large flat PCB with traces under it. You could design the board to not just have the traces, but also the control circuit. The problem would be thermally isolating the control board, but it might be doable. Perhaps also have holes to attach an aluminum plate to the board to act as a head spreader