I have a pololu simple motor controller. I use a potentiometer connected to the analog pins and it works fine. However I need to substitute the pot with a ratiometric hall sensor so to provide control signals to the 3 analog pins of the controller. A ratiometric hall sensor seems similar to a pot, but after a week of reading and experimenting I realise that its not that simple. The specific question : can the simple motor

controller accept a control signal from a hall sensor?

Thanks Phillip

Hi Phillip,

Do you have a circuit Diagram of what you have working with the potentiometer and what you want to have working with the hall sensor. Also a link to the hall sensor so we can see what we are workign with.

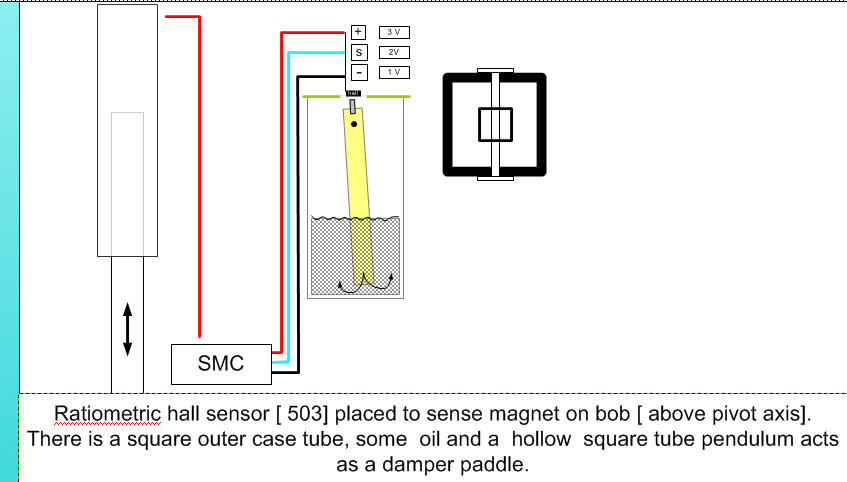

Hi Clinton https://www.spelektroniikka.fi/kuvat/c503.pdf

that’s the link to the hall sensor I am experimenting with

and there is an attached drawing showing the application. All aspects of the tilt sensor work very well and there is a nice voltage signal and friction free motion. The point is to get a non contact sensor that puts out a signal consistent with pendulum position… this works. " but." I cant get the hall sensor signal to work with simple motor controller. I don’t have any internal diagram of the controller but there are 3 analog pins 1] power[ about 1.6v 2] earth [ shows about 2V] and signal input.

First I tried a simple swap of the pot with the hall… ’ signal not recognised’ Then I tried a separate power supply to the hall and put the signal from the hall straight into the controller signal input pin [ the user manual allows this as long as the voltage does not exceed 3.3v] so I used resistor to keep the voltage acceptable. This way the signal was recognised but it could not be " scaled’.

Now… just a moment ago I rigged the hall sensor TO the pot and had a small step fwd. Now I can

control the electric actuator with the hall sensor magnet. ‘but’ there is very limited ability to tune the response of the controller.[ Which is important]

I am however now convinced that a hall sensor can indeed interface with the controller.

But I really don’t understand what I am doing!!!

Do you? cheers P

correction ; 1] power[ about 1.6v 2] earth [ shows about .2 v [ 2/10 of a volt] and signal input.

P

Hi Phillip,

Is this an inverted Pendulum style problem? If so you will probably need some kind of microcontroller to process the feedback from the hall effect sensor. What you have described sounds like proportional control where you are scaling the feedback by a set amount.

hi Clinton no microcontroller needed. but it is an inverted pendulum type problem. Any sensed imbalance will cause the hall sensor on the pendulum to supply a signal to the controller and the controller adjusts the " platform via the electric actuator and as the platform comes back towards balanced the hall sensor varies its signal. Gravity closes the loop. That’s why the hall signal and the tilt sensor need to be precise. Also that’s why the controller needs to be programmable for response characteristics

I have solved the problem .

To use a 503 hall sensor to communicate precisely with the Polulo simple motor controller I used a 2k potentiometer with the hall sensor pins wired into the pot. Power and earth and signal on the two items connected. Open the programming centre and scale the pot [ centralise the signal values], then lock the pot position and use the hall sensor magnet to control the actuator

The response is progressive and programmable. There may be a better value of pot to refine the result but for the moment I am happy with it. For example a 10k pot gives a poor result with the hall sensor. cheers and thanks for input P.

What do you mean by a poor result? I am curious to see how this goes, My guess is that the liquid would slow the poles and the tube stops it from getting too far from its operating point making proportional control an option. Is the poor result a long settling time?

hi there are two separate points, first, the polulo simple motor controller is a very good controller that can be programmed for acceleration / speed/ braking/ start point etc. One way to control it is with a pot or you can control it in other ways which I am not confident with.

The second point is the tilt angle sensor MUST be friction free and the damping must be able to be varied [ oil viscosity]. for example if I was to use a potentiometer as the signal generator and connect it to the bob axis there would be too much friction[ even after washing the grease out and prying the wipers to relieve drag on the tracks] So, that’s why I wanted a contactless sensor [ hall sensor] .

When I say I got a " poor result’ with a 10k pot connected to the hall sensor I mean… when the magnet passed by the hall sensor… the electric actuator " took off" one way or the other without any progressive/ smooth start and stop. in other words. I could not programme the controller for smooth motion of the actuator. But when I changed the pot to 2k , then the hall signal was observed by the controller in such a way that the motion was smooth and it could be programmed for special effects

I am not into electronics but mechanical engineering is not a problem. I still don’t understand " why’ I just observed and experimented and now as the magnet moves from the null position in either direction there is a very smooth response by the actuator via the controller. Even though the total movement of the magnet is no more than 3mm it provides a very smooth signal each direction.

I guess that the controller must need the signal to be in a defined condition and the 2k pot creates this. I would like to know ’ why’

Cheers P

more about the damping. without oil you can set the pendulum rocking and it will rock for a minute on its spindle before settling but with suitable oil it will follow an inclination smoothly and not overshoot. vibration does not worry it and even heavy shocks only create a momentary reaction before resettling. Oil damping is an effective and easy way to tune the system

My guess without being able to play with the circuit and model would be that the 2k pot would allow a higher current in the hall effect sensor which would be more resistant to change.