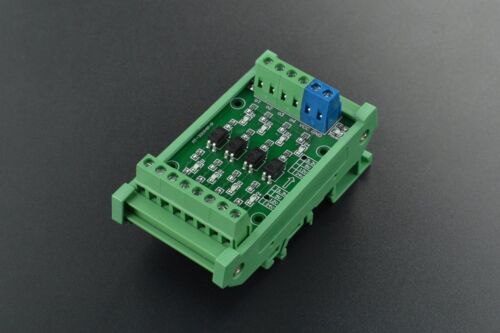

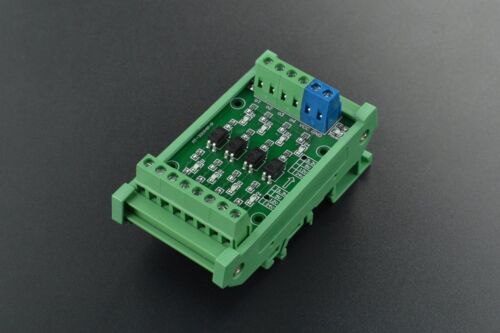

This is a placeholder topic for “4-Channel Level Converter (12V to 3.3V)” comments.

This 12V to 3.3V level converter module with 4-channel photoelectric isolation features common anode / common cathode / differential signal inputs. The…

Read moreThis is a placeholder topic for “4-Channel Level Converter (12V to 3.3V)” comments.

This 12V to 3.3V level converter module with 4-channel photoelectric isolation features common anode / common cathode / differential signal inputs. The…

Read moreI’m looking at the 12v-3.3v converter (DFR0913) to tell me when a 12v circuit is active. From the description, which mentions differentials, I’m not if a 12v signal will give me 0v or 3.3v at the output. Would I need the pnp or npn version to get a logical 1?

Thanks

The schematic for each channel and some connection diagrams, including differential input, are available at the product wiki for the 2-channel version.

12 to 3.3V 2-Channel Level Converter / Shifter Wiki - DFRobot

Thanks for the speedy reply and very useful reference.

Jon.

I have a photo sensor that outputs PNP at 12v @25mA and say I connect it to the 12v side of DFR0913… can this switch the 3.3v side ( level) high?

Hey Ventaka,

Welcome to the forums!

From what I can tell with your project, if you are looking to use a Photo PNP sensor through this Logic Level Converter, it should be able to do what you are after. Keep in mind that this product does have a couple of different configurations dependant on what you are looking to do. You can find the best configuration for your project via the Wiki as it will also be able to give you an example connection Diagram to help understand how this product can help in your project.

Cheers,

Blayden

Thanks for the reply.

I can’t find the minimum current required in the product wiki for the 12v input side of this converter.

I am using this DFR0913 as a switch so if this module can shift the corresponding 3.3v level to high when a current of 25mA is applied at 12v side …it solves my purpose. If this is possible then I can order this otherwise I have to search for some other module/converter.

Refer to the answer to my original question - it sets out how to make the output side go high or low in response to a high input.

Hi Venkata

The input circuit has 2 LEDs each driven via a 270Ω resistor. If the LEDs drop something like a bit over 2V then this means about 35mA through each LED. Possibly a total of 70mA, a bit much for your sensor I think. As one of these LEDs is only an indicator the track could be cut to disable this one (there is an indicator LED on the output so really not needed) which would reduce the current somewhat. There is nil info available on that Opto Coupler so can’t say exactly but this sounds a lot for these devices. They are usually happy at something like 10 to 20mA. If they will work effectively at a lower current you could put another resistor in series with the input to reduce the input current to a more manageable value.

Cheers Bob

The current is determined by the load (ie, the converter) not the supply. You can get a rough estimate of the load from the schematic - 2 parallel 270Ohm resistors each in series with a diode - if you assume a 2V drop across the diode. Is the 25mA you mention for the 12V supply a maximum, or just a typical?

Thanks a lot for the replies … the Current/load Specs of the Photosensor is as follows.

Consumption current:

= Lower than 30mA at voltage 12V DC

Control output Max. load current:

= 40mA Light ON/, Dark ON, Switchable , PNP

Power Supply For powering the Sensor:

= DC-DC Converter (Regulated 12v 125mA)

I mentioned 25mA instead of 40mA just to account for the safety factor. If DFR0913 can switch at 12v/25mA then it should be reliable enough at 12v/40mA.

It would have been really helpful if DFROBOT mentioned the minimum current required at 12v input side for level switching. Hope they add this spec in their datasheet.

Hi Venkarta

The load current for the converter is going to be dictated by the LEDs and resistor values. Like if you connect 12V to the input and measure the current that is what it is or going to try to be, irrespective what you are going to drive it with. You just have to supply the drive current it will require.

I suggested above you disable the input LED, that will cut the current used to about half. Any further current reduction can be done by adding some resistance in series with the input, as I described above.

You are absolutely correct here. But getting that sort of info out of some of these suppliers is extremely difficult. I get the impression sometimes that they just don’t know or they don’t care as long as they keep selling these things to the unsuspecting customer. Even if they put the type of Opto Coupler on the circuit diagram that would help. One could then look up the data sheet for that device. Some of these manufacturers even remove any marking on the component so it remains a complete mystery.

You might have to experiment a bit. I would think most Opto Couplers would operate at 20mA which your sensors should handle OK.

Cheers Bob

By the way the load current has to be supplied from the 12V supply so I don’t know how the supply is <30mA with a load current capacity of 40mA. Unless that 30mA is the no load consumption and the 40mA (or whatever the load current is) has to be added. Would be worth checking this. That is for each sensor so your 125mA supply won’t power many devices.

Another tip. If you are going to measure current with a meter in series use the 10A range. The lower mA ranges will have too much voltage burden and insert a relative high resistance in series with the DUT and you won’t get a correct result.

Thanks a lot for the reply… yes the consumption current is at 30mA (No-Load) and 40mA for the Load so its 70mA in total. The dc-dc converter 12v/125mA is already placed in the circuit. This is the only sensor for the application at present. A 2-channel level-shifter version may be sufficient for me (if it works).

I thought this DFR0913 out-of-box would solve my purpose but it is more likely that I need to cut the led off and add a resistor. It does not justify to buy 25 units , hack-it and install at the customer place.

So I think I better look for an alternative level-shifter than DFR0913.

Thanks once again to everyone for helping me to decide.

Hi Venkata

Keep in mind the level shifter does not have to use all that sensor current as long as it supplies 12V. Some of the simple high impedance VOLTAGE level converters might do. The one you have quoted has the advantage of being optically isolated BUT enough current has to be supplied by the driving device to operate the LED in the Opto coupler. Like I said, 20mA is usually plenty so I don’t know why all the current. Also with only 270Ω limiting resistor for the indicator LED should have it lighting up like a search light.

Do you actually have one of these converters? As the current seems excessive I wonder if that circuit is correct and the 12V version actually has much higher resistor values. That 270Ω is about the value I would expect for a 5V unit. That would be about 10mA current for each LED, total about 20mA.

That might be worth investigating. If I am right the device should work as you say “out of the box”.

Cheers Bob

Hi Venkata

Just spotted this

This is looking like a commercial venture.

If that is the case I will have to leave it here and take no further part in this discussion.

For a start if things go awry I do not have Professional Indemnity Insurance so I will divorce myself from this discussion but feel free to take note of any of my observations or suggestions but it is all up to you.

Sorry about that.

Cheers Bob

Hi Robert,

Yes, you are right this is a commercial venture indeed. I have no intention to hold anyone responsible for their advice. Its a free advice but with a lot of experience. Experienced guys out there like you help people like us to arrive at a decision. I own my decision either right or wrong so I don’t hold anybody else responsible.

I don’t have the DFR0913 with me to test. I have to buy and test and if I have to hack-it then its not worth it. Let me look at other alternatives that confirm a 12v/25mA and come back here.

Hi Venkarta

Fair enough. But there have been others in the past who have presented a problem or project which turned out to be a commercial venture. A good percentage wanted (or needed) the forum to do everything for them including research which I personally think is a bit off. In reality the research is all part of the learning curve and you are not learning much if this is done for you. I think Core will tell you this Forum is aimed at helping the maker, experimenter and general interest not a commercial consultancy. You have at least indicated that you preprepared to do some if not all your own searching which is a start.

If you are only concerned about converting 12V to 3.3V then disregard the 25mA unless you want to go down the opto isolation path where you will need a bit of current to drive the opto LED. There are lots of ways to do this from the very simple voltage divider to quite exotic means. But for isolation the opto approach is probably best. The thing to remember is that if you use a common source to power everything you really have lost the complete isolation provided by the opto system.

Cheers Bob

For that scale of project you need to invest some seed funds. Buy one unit and check it out. The notation on the schematic says “When other different voltages and levels are converted, the resistance values in the diagram are different.” so you need to examine the actual values of the resistors on the specific unit you are evaluating for the customer.

Hi Jeff

That is probably the way to go BUT!!! If one had confidence in the accuracy of the provided schematic and info you would not have to do that. Imagine the uproar if you had to buy and reverse engineer or generate your own test report for every bit of kit you purchased.

I think you would have to admit that 35mA is a bit over the top to drive a LED, in this case even the indicator LED. That is why I suggest this circuit is possibly for the 5V to 3.3V version. Even publishing the Opto Coupler type would be a help.

Cheers Bob