This is a placeholder topic for “Mini Analog Joystick - 10K Potentiometers” comments.

Sometimes a simple analog control device can be the perfect tactile solution for your project, but they can be surprisingly hard to come by. Luckily Adafruit have found … read more

Read more

Do you have a similar joystick with a pushbutton on the top?

Hi Luke, welcome to the forum!

We sure do have a couple of similar options with a pushbutton on the joystick itself. In fact, I think we almost have too many!

The best options I can find for a joystick with the bare potentiometers available like the above product is:

Alternatively, we have a few available on a nice breakout board:

Or an I2C option:

I’m building a custom joystick (looser response and between-the-legs ergonomics) and so far have used one of the standard arduino-compatible analog thumb joystick modules to drive it. It actually works better than expected, but it’s not ideal; when I put a full-size joystick handle on it, there’s a significant dead zone in the middle which is simply caused by the inherent wiggle in the component’s little springs, multiplied by the leverage of my grip.

I’m considering trying this thing, but it’s quite expensive. Would it be easy to adapt like my prototype and put a handle on it; would it have a smoother response than the cheaper units? Is it possible to guess?

Hi Colin,

Welcome to the forum!!

Very interesting mod  Yeah definitely, you’ll have to make a couple more connections though since the two potentiometers are completely disconnected vs the nice PCB that comes included with the joystick you are currently using.

Yeah definitely, you’ll have to make a couple more connections though since the two potentiometers are completely disconnected vs the nice PCB that comes included with the joystick you are currently using.

Another part that would be worth looking at is this one from Pimoroni: Pimoroni Joystick Australia

PS: the ball on the top is removable!

Liam.

$13 looks nicer but those clicky arcade joysticks have digital switches don’t they - I’m making an analalog joystick for a flight sim, so degree as well as direction is definitely needed!

How tall is that thing - I am building something flat enough to go on the chair with me!

Hi Colin,

Yeah it does look like it, based on the photo the base looks to be around 30~40mm.

Hi Colin,

If you need more resolution, or a customisable deadzone, or the perfect feel for you, I’d recommend using encoders and a spring. You can get encoders that go up to an eye-watering 20,480 Counts Per Revolution, so it’d be able to detect movement of up to 0.017 degrees! (You may need to go lower if your microcontroller can’t handle that. Here are some examples of such encoders:

I’d design a 3D printed joystick with bearings if it was my project, but I get that not everyone has access to that

Since the Pi Pico has PIO that can read encoders nicely it seems, and HID built-in, you might want to look into whether you can get your own joystick happening:

Keen to hear your thoughts!

-James

Hi all

Could be wrong but I think most flight sims are expecting analog inputs or at least the ADC output from such a device. Not quite sure how the whole thing works but I would imagine the encoder would be like lots of button presses.

I think the Arduino Teensy supports analog input and simulator output (whatever that is). I personally have XPlane 10 and a Leo Bodnar board with success. Especially the support for up to 16 rotary encoders (I currently use 10). I was not aware of Teensy when I purchased this board.

Cheers Bob

Hi James,

Very interesting suggestion! That might be a good idea. I’ll consider this, along with buying and using Hall Effect sensors directly.

I’m running up against the limits of my expertise as a mechanical engineer. I’d like a joystick with a little resistance but no self-centering spring. There must be little components that could accomplish this (constant friction) but I don’t know what they are called!

The microcontroller has to explicitly output the joystick axis value, so whether you read from the ADC or get it via some other method (like an I2C ADC or a rotary encoder) it’d amount to the same thing. So this is an interesting approach.

Hi Colin

I am not using rotary encoders for any analog axis like pitch and roll. They appear in the flight sim as switches(like pushbuttons), 2 per encoder, one operates in the cw direction and another in ccw. I then map these switches within the flight sim for Nav1 and Nav2 radial select and tuning. 3 are for NDB tuning. The 10th I use for elevator trim, replacing the switch on the yolk. Could do it all with mouse button presses but using the encoders adds a bit of realism.

Cheers Bob

Aha, that’s an excellent use. I guess the real devices have rotary encoders on them just the same. I’m working on a glider sim. This leads me to my next question which I posted here. Unfortunately though I can solder and code the mechanical stuff is a bit tricky, since I don’t have the training to know what things are called nor the library of spare parts lying around!

Hi Colin

The analog axes are potentiometers.

Cheers Bob

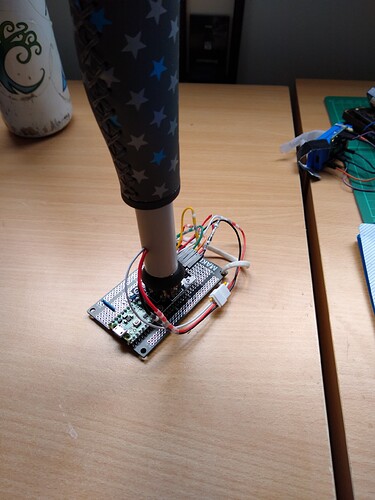

I ended up getting one of these and it’s a significant step up from the thumb-pad style joysticks for my project:

This will do for now. Over time I am going to try and build a joystick from scratch - print the gimbal and use some bearings, magnets and hall effect sensors for the electronics (instead of pots) for the next version.