Hi, I’m trying to make a wicked the musical moving cake. I only need one tier of the cake to move and the top 2 tiers to remain still. What motor do I need to buy for this please? If you google moving wicked cake you’ll see an example of what I need. I’m stumped! Hope you can help. Cheers. Paula

The rotation speed in the video is about 7 seconds which equates to 8 RPM.

Standard electric motors rotate between 5,000 to 10,000 RPM. With gearing the RPM can be reduced.

But I haven’t seen anything less than 14 RPM. At this speed the motor has a huge amount of torque. Meaning anyone touching the moving part could cause the cake to fall apart.

My guess is the cake in the video is using a Stepper Motor. The complication with this motor is you need something to generate the pulses to the motor at the right rate. A standard motor would require only a battery and a switch. Links below to some Core Electronics Stepper motors. The cheap one may not have enough power to turn the platter. The more expensive one is an over kill and probably has too much torque.

A circuit to generate pulses could be quite simple or complex depending on what you want the moving parts to do.

Inside the rotating level I imagine there is a box with a circular platter that rotates, to which extensions can be attached and decorations placed on the arm that extends beyond the cake.

All the best. I can think of other ways to do this using belts and such, hope this gives a starting point.

Jim

Thanks James for your detailed reply, I really appreciate your advice and suggestions.!

Here’s a few photos of what she’s done!

image|231x500

Interesting. And something I did not consider. Use of a wheel the drive the platter.

I think a stepper motor with a pulse circuit that can be varied might be simpler mechanically.

Something like a Pi Zero as the control device would allow sound, LED lights and other movements; which could all be controlled remotely via Wifi or Bluetooth from a phone or tablet. Put all that inside a sealed container and the cake tier could be built around it. Ideas …

Think I might have a new project.

Anyway … Cheers

Jim

Thanks James, if you could build me one I’d be more than happy to buy it off you… it sounds awesome!

Cheers

Paula

Designing something like this is an interest to me as it involves mechanical, electronics and programming. The pics are a very rough proof of concept from stuff I had in my workshop, put together in about an hour or so. Final design would be in sealed plastic box, use perspex for disk, (NO WOOD), and be suitable for use in a food product.

Pros:

- disk rotates about 6 seconds per revolution

- it is stable on the bearing

- Works best around 3V.

Cons:

- motor gears are very noisy (might be less when inside a case)

- motor draws about 700mA (battery power not an option)

- it is too tall for an effective device

- motor gets warm after a few minutes

I tried a continuous rotation servo, but it was not good at slow rotation speed.

Both designs rejected.

I have ordered some cheap Stepper Motors, should arrive in next day or two, will see how they go.

(have never experimented with these, so good learning experience for me)

Regards

Jim

PS I am making this as an interest in electro-mechanical design more than as something to sell.

Oh wow I wouldn’t know where to start to be honest, wish I could do something like you but sadly I’m not that technical.

If you do succeed in making one and would be interested in selling then please contact me and I’ll gladly pay for your time, effort and parts.

Cheers

Paula

Hey Paula and James,

That’s excellent! If you’d like to process the project to our site we’re also offering store credit rewards for helping us write it up for you. You can find it all at the link below. Have a great day!

Bryce

Core Electronics | Support

Stepper motor testing. (these posts will be the research and design phase)

The operation of Stepper Motors is; move, stop, move, stop etc, in very precise steps.Smoother movement is possible by using many steps so it appears to be one continuous movement. I was able to achieve this using the parts below, but the stepper motor is not strong enough to turn the platter nicely. It is rated at only 100 grams / centimetre traction torque.

Rotation peed 10 seconds, motor set to 1/16 micro step, smooth enough movement.

Motor has 48 steps per revolution, micro step 1/16 = 768 steps. 13 millisecond delay between steps.

Will certainly find a use for this is future robotic projects.

Path ahead decision:

Stepper Motor (a stronger one) or normal DC motor geared to 6 RPM ??

- No geared motor actually goes as low as 6 RPM so extra gearing would be required. See the pics in a post above where a wheel is used to drive a platter.

- Stronger stepper motor might not produce the desired effect.

Think I will look at both options.

Regards

Jim

Stepper Motor test Parts

- Small Stepper Motor SKU: ROB-10551

- A4988 Stepper Motor Driver Carrier SKU: POLOLU-1182

- Pololu 5V, 2.5A Step-Down Voltage Regulator D24V25F5 SKU: POLOLU-2850

- Uno R3 SKU: CE05629

- 12VDC plug pack, 100uF capacitor, vero board, various connectors and sockets.

Looking at using this stepper motor, 2kg per cm, 200 steps per revolution, 12VDC 350mA, will work with current motor drive pictured above.

Brilliant Jim, well done!

I’ve actually bought a rotating turntable that you can display items on, I thought I could take it apart and see what was in there, I ordered it from amazon, it hasn’t arrived yet but I’ll post a pic of the inside when it arrives.

I’ve got to make the wicked cake next week, it might not have the spinning component but I’d still love to know how it can be created so I can use it for other cake designs.

Cheers Jim I really appreciate your efforts. Paula

Cheers.

Designing something can take a lot of trial and error, probably what I like about my hobby.

Eventually seeing it work is reward in itself.

BTW Core Electronics made a liar out of me. Below is a geared motor at 6 RPM. This might be what the project needs, LOL

Regards

JIm

Oh my gosh if I had to design this it’ll take me forever and I’d probably still not have a spinning platter lol!

I look forward to seeing your design.

Cheers

Paula

Hi Jim,

I’ve been digging around on Facebook again and look what I’ve found!! She’s explained how she did it!!

Yes.

I realised last night; that just rotating a disk did not allow for anything above. I was too focused on the electronics and not the mechanical design.

In the pic it looks like the two metal plates have a ball bearing race between them, probably the top plastic disk was originally attached to the top metal plate. The electric motor drives a wheel which rotates the top metal plate on which you attach some extensions for decorations.

This is the path I am now following.

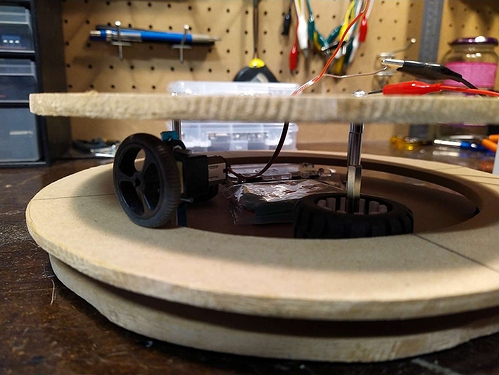

Today I put something together out of wood (easy to work with) just to prove a concept. Top and bottom solid disks, don’t rotate and rigidly attached to each other so stable overall. Middle disk is driven by an electric motor and wheel similar to the pic from Dawn.

Middle disk rotates on caster bearing wheels and internal poles with circular nylon standoffs. Ensures the disk remains in place as it rotates. Put together from stuff I had in my workshop. The middle disk is about 11" in diameter with a 10" diameter hole cut in it. This allows for a solid connection between the top and bottom disks using standoffs. There is enough room for more than one motor (if needed), a Raspberry Pi Zero for Wifi activation and sound. A good size LiPo or NiMH battery can also be also be installed. Overall height would be about 5 to 6cm.

The parts I have chosen are available from Core Electronics. I intend to write this up as a project when I get a good working model. At the moment it is very rough and no pics, there are still a few bugs to sort out at this time.

Cheers

Jim

EDIT: Just found the swivel turntables that Dawn has used on AliExpress. 3" 4" 6". Might be better option than trying to build a platform and might rotate better. Still I would like something larger than 6" for 12" cake. Options … options … decisions … LOL

Wow, I’m so impressed, you’re a genius!

Update:

Waiting on parts to arrive, could be a while.

Keep in mind this is a very rough proof of concept. Final version will be made from laser cut acrylic sheet and look much nicer. Unsure this will be the final design; I have another similar one in mind that might be better and more robust. Both the top and bottom disks would support the middle disk, with the motor and electronics underneath.

The middle disk takes 2 seconds to rotate, it extends beyond the other disk and allows attachment of various decorations at various intervals. The green battery would last 1.5 to 2 hours from full charge. If the display needs to run longer, the final will have an option for using a 12VDC plug pack. The Raspberry Pi Zero and battery are to show how it would eventually look. It will also need another small circuit to drive the motor, an on/off switch, power supply and socket for plug pack. But the general idea is there …

The motor is too fast for this design but was what I had in my parts bin. It is 320RPM; waiting on 98RPM motor. I have another motor in mind that is stronger and more robust, also might be quieter. It would be used in the other design.

I only had 2 wheels in my bin; the third would go where the pencil circle is; so the middle disk would be nicely supported between the 3 wheels.

A problem with this design is the middle disk is only held down by the motor on one side, the disk could be dislodged lead to damage. Also, the tension on the motor to keeping it running on the disk, is hard adjust and hard to fine tune.

Anyway, thought I would post something to show it is still in progress.

Cheers

Jim

You are a legend Jim… thank you for the update and hard work!

Cheers

Paula

This is where the project is at this time, but most likely wont be continued as I have achieved what I wanted to achieve. It has been an exercise is mechanical design more than electronics or software. An area I am not proficient in. The project has gone through a number of design changes, I have experimented with Stepper motors, a worm dive motor and various ways of getting the platter to rotate.

The design here is the best of all my efforts. The platter moves nicely, it can be varied from 6.5 seconds to 20 seconds per rotation by the PWM signal from the Raspberry Pi. Two of the motors are a little noisy and overall it is more noisy than what I would like. The stepper and worm drive were just as noisy.

If it was to continue it would have a sound output to paly music files and connection for lights. The Raspberry Pi would be controlled via a web page. The device would act as a Wifi hot spot for connection via phone or tablet. These are all things I have achieved in other projects.

A 6 cell battery holder would fit nicely between two motor brackets. A speaker would fit between another two brackets. The final design would be made of laser cut acrylic sheet, the gaps between the top and bottom would be filled with acrylic rings and only the platter would extended beyond. This might reduce the noisy level.

Anyway it has been a fun trip and I have learnt a lot.

Cheers

Jim

Lower board showing caster bearings over which each motor is mounted.

Platter mounted. It is securly held between the 6 wheels.

Top board in place.

Side view. (yes one of the wheels is not touching, it would be adjusted if operating)